Who We Are

HiPlastics, who is a manufacturer specializing in the plastic products for retailing, has a rather simple philosophy –“Love then make better”.

We build the Better part, for the Better price and always deliver On-Time. When you combine these three strategies into a single goal, it leads to satisfied customers. This is how we think, how we work and what we promise. It is why our customers keep coming back.

HiPlastics has been providing plastic products to the world since 2010. Our commitment and loyalty to excellent service makes us your better choice for attractive, top-quality products.

As an expert manufacturer in this industry, we can react quickly and create bespoke solutions to order. We believe in exceeding our customers' expectations with exceptional service and value.

What We Do

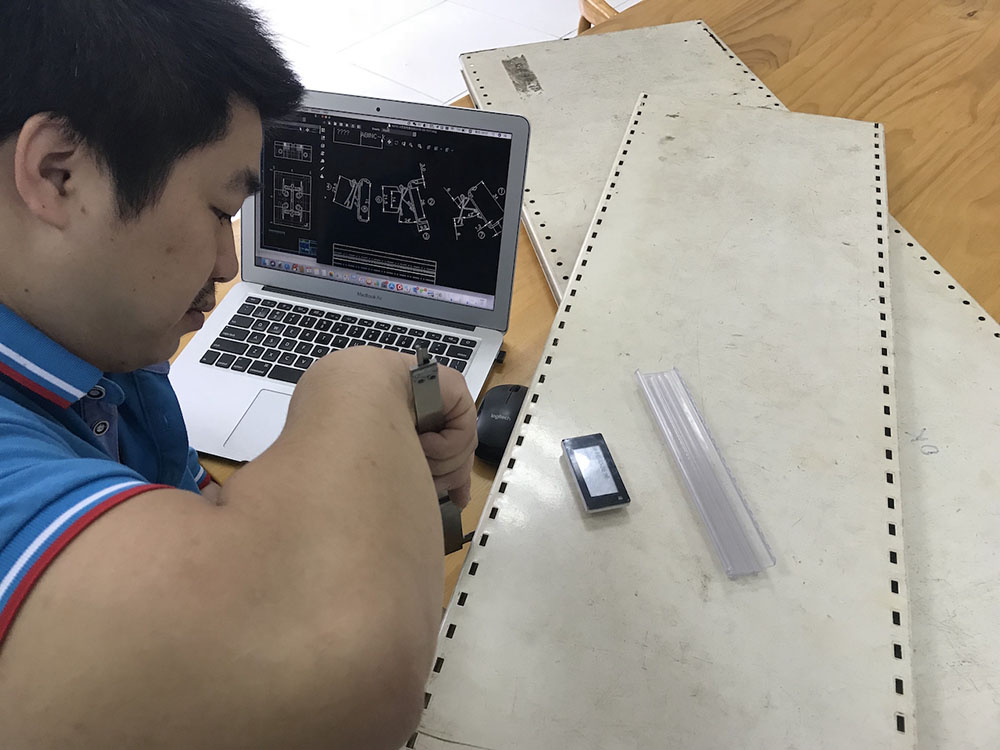

DESIGN AND PROTOTYPING

HiPlastics offer a complete service, from the initial concepts and Site Visits through to pro-totyping and production. Our design team is constantly developing new ideas the latest computer technology and materials. Our standard products can be modified in design and materials to suit your requirements. Inspiring solutions to your requirements with a service that includes pre-production prototypes for approval and suitability before roll out.

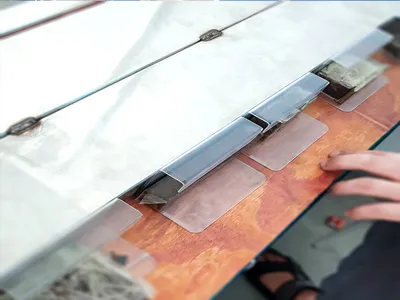

PLASTIC EXTRUSION

Plastic extrusion is a process where polymer compound pellet is fed from into of the ex-truder and heated to a molten state, the material is then processed through the extruders which forces the compound material through a die that carries the shape of the profile re-quired. The extrusion is then cooled and formed to the correct shape and then cut to the specified length.

PLASTIC INJECTION

Plastic injection is a process used for manufacturing products or parts by injecting molten material into a shaped mold or die. The molding involves melting granular plastic pellets into a liquid form and then compressing this liquid into the empty cavity of a mold tool. The plastic will retain the shape of the mold as well as the surface texture of the walls of the cavity.

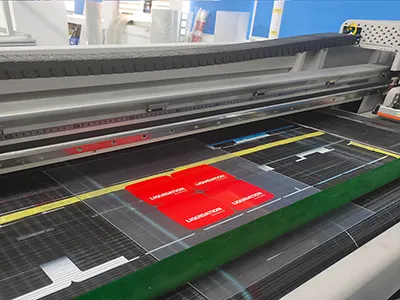

HOT BENDING AND PRINTING

Our hot bending products use advanced machines, automatic instant forming, with accurate Angle, fast speed, high efficiency, no foaming advantages. At the same time, our laser printing technology converts what we want to print into a pixel-by-pixel bitmap image on a photosensitive drum to produce a printed product.

Why Choose Us

Manufacturer Specializing in The Plastic Products for Retailing

High-level Machining Ability

We pride ourselves on providing superior service and products to our customers. Our machining offers great turn-around time, competitive pricing, and superior high quality.

Strong Design Ablity

Our team has experience in all fields relating to product design and development. If you have any needs for your new product or wish to make further improvements, we are here to offer our support.

Responsibility and Accountability

High quality materials are the basis of every successful plastic product we offer. We focus on uniform properties and low variation, so that performance is predictably reliable.

Free Samples Available

One of the biggest worries when purchasing from a Chinese supplier, especially for the first time, is that when the goods arrive is it exactly what you want. Our samples procedure takes away that worry completely!

Stable Quality

Our service includes regular and thorough inspections throughout the manufacturing process, eliminating the need to employ additional quality control inspectors.

Responsive - On-line 24 Hours

Our sales and our follow-up service is one to one. If

you

have

any question, we will respond to you within 24 hours.